How to treat Cement Tiles

Today, cement tiles are back in vogue, forgotten during the dominance of ceramics, they have become the object of study and research by many interior designers who have valorized their versatility and aesthetic potential.

Concrete, a popular, durable and inexpensive material, destined to take center stage in new projects.

To maximize its beauty and preserve its integrity, however, it is necessary to treat handcrafted concrete during installation.

In this article we explain how to do it in 4 steps.

1. Cement: from popular to renewed design element

With their history, cement tiles express an ideal of pure and noble beauty. They do not tell of the splendor of the aristocratic era of majolica and Venetian floors, but of the more popular era of suburban construction, which, thanks to this solution, granted everyone the pleasure of decorating their homes.

Also known as cement pastine or cement pots, cementine began to spread in the late 1800s, with the onset of the industrial revolution and the increase in population that in large cities led to a mutation of housing solutions and the need to build new houses in less time.

Cement tiles are made from a mixture of water, white cement, marble powder, mineral powders and natural dyes, they proved to be the ideal material because they were cheap, durable and quick to lay.

Practicality was also combined with elegance expressed by geometric and floral patterns, an aesthetic that at the turn of the 19th and 20th centuries made the history of cement as a flooring material before it was replaced by ceramics.

Today, in the midst of a retro revival, they are back on trend, representing an excellent choice for modern, eclectic decor, especially when paired with more contemporary solutions.

Read on to find out how to treat handcrafted cement tiles.

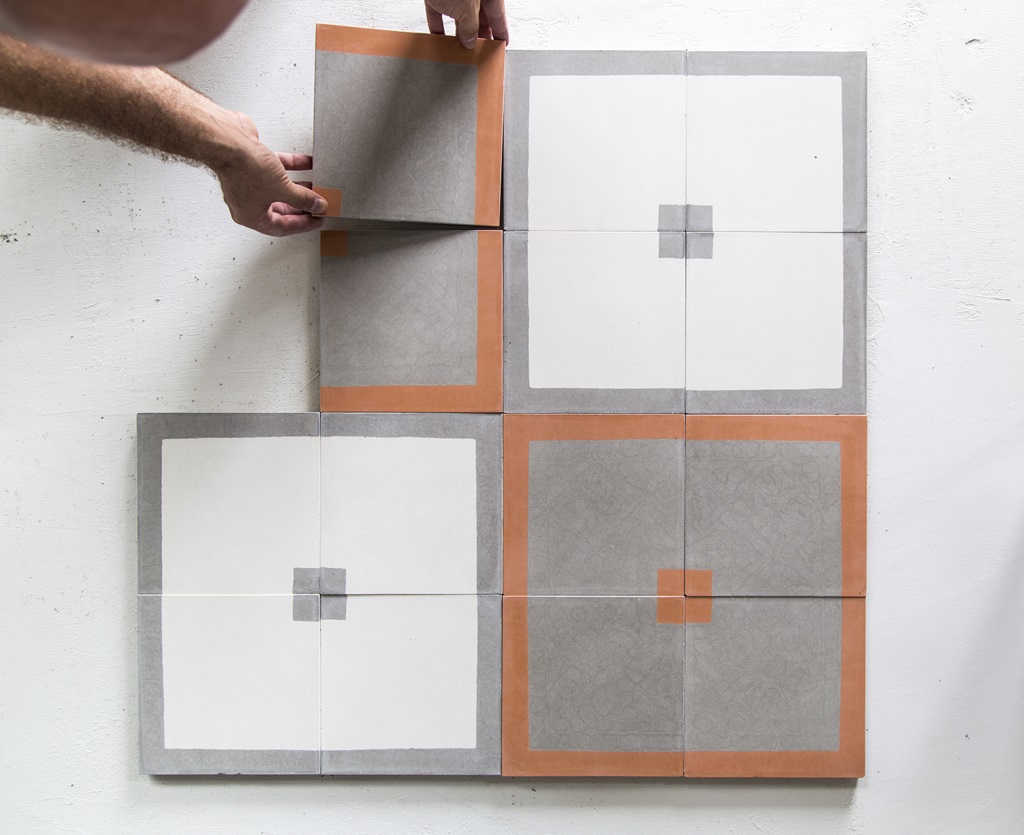

2. Reclaimed cements and new collections

Thanks to their multiple potentialities and ability to adapt to different styles-from industrial to contemporary, from rustic chic to new vintage-Sicilian cementines are going through an interesting moment of rediscovery for both the salvage market and the design sector. If salvaged cementines represent a risk by posing the problem of limited quantities and binding stocks, a different matter applies to designer Sicilian cementines that allow architects to experiment in total freedom with new solutions through unusual formats and colors that deviate from the more classic, industrial-style ones. This is the case of the Sicilian cementine collections of Fangorosa, Zagara and Sicano , made in collaboration with the artisans of Comiso (Sicily), a reality that still works cement preserving the peculiar decorative traditions that developed in the Mediterranean basin that includes Spain, Morocco and Tunisia.

3. The steps for treating cement tiles

Today, the renewed interest in cement tiles is not only reflected in the recovery of old and existing floors but also in the installation from scratch of cement tiles that reinterpret tradition in new ways.

Here’s why treating artisanal cement:

– maximize the beauty of the concrete floor

– increase its resistance to external agents, whether physical or chemical.

With this in mind, Fangorosa, after thorough testing and research to find the best solution, has identified two 4-step treatments, one to treat exterior concrete surfaces, the other to treat interior concrete surfaces laid on dry, planar and compact screed. Both include four products that are water-based and entirely sustainable.

The Interior Cement Kit contains:

- PART A Pre-treatment

- PART B Washing

- PART C Treatment

- PART D Finishing

The Outdoor Cement Kit contains:

- PART A Pre-treatment

- PART B Washing

- PART C Treatment

- PART D Finishing

The Steps for Cement tiles Treatment in Detail

Cement is treated in four different steps, pre-treatment, washing, treatment and finishing, Let’s find out about them in detail.

There are four steps that installers perform to treat cement for both exterior and interior cement surfaces.

- Pretreatment: The first step for the maintenance of the concrete necessary to make it water-oil repellent in the phase after laying and before grouting

- Washing: during this stage of cement treatment, site residues and surface grout are removed. This is done using a neutral detergent, which is less aggressive and impactful than an acid that could corrode the surface.

- Treatment: the treatment of cement tiles aims to make the floor hydro – oleo repellent and consequently also the cementitious joint.

- Finishing: The application of wax concludes the cement treatment and is the element that differentiates the two kits, for indoor and outdoor surfaces. Wax for exteriors revives the tones of the pavement and protects its surface from wear and tear

The treatment for outdoor concrete surfaces has the function of protecting the coating:

- from freeze/thaw cycles

- from possible stains

- from the occurrence of moss and lichens for this reason it is anti-vegetative

4. The Tools to treat cement tiles

Cement is treated outdoors and indoors with two tools, let’s take a closer look at them:

- Fleece (or cotton cloth) useful in 3 stages of cementine treatment (pretreatment, treatment and finishing) to expand the product on the surface, evenly and without residue.

- Pad: cement care tool used in the second step, washing, to create an abrasion on the surface of the cementine so that it opens its pores for the next steps and can then fully absorb the treatment

Now you know how to treat your cementines, Fangorosa’s Kit also comes with a technical sheet explaining the characteristics of each product and instructions for use, step by step.

Fangorosa’s Sicilian cementine treatments are sustainable in that they are designed not to be aggressive on the coatings, and are natural and water-based.

Also discover treatments to maintain marble and terracotta.

Follow our Instagram page so you don’t miss any news.